JOINT VENTURES & Technical Collaboration

Joint Ventures

Atlas takes pride in its flagship joint venture partnership with Honda Motor in the manufacturing of 2 wheelers and 4 wheelers. As a result, Atlas has strategically developed a robust ecosystem through joint ventures and technical collaborations with globally renowned parts manufacturers. Together, we drive cutting edge automotive solutions and optimal QCD results.

Daido Kogyo Co. Ltd.

Denso Corporation

Gongcheng Chongqing Investment Co. Ltd.

Daido Kogyo

Co. Ltd.

Denso Corporation

Co. Ltd.

Gongcheng Chongqing Investment

Co. Ltd.

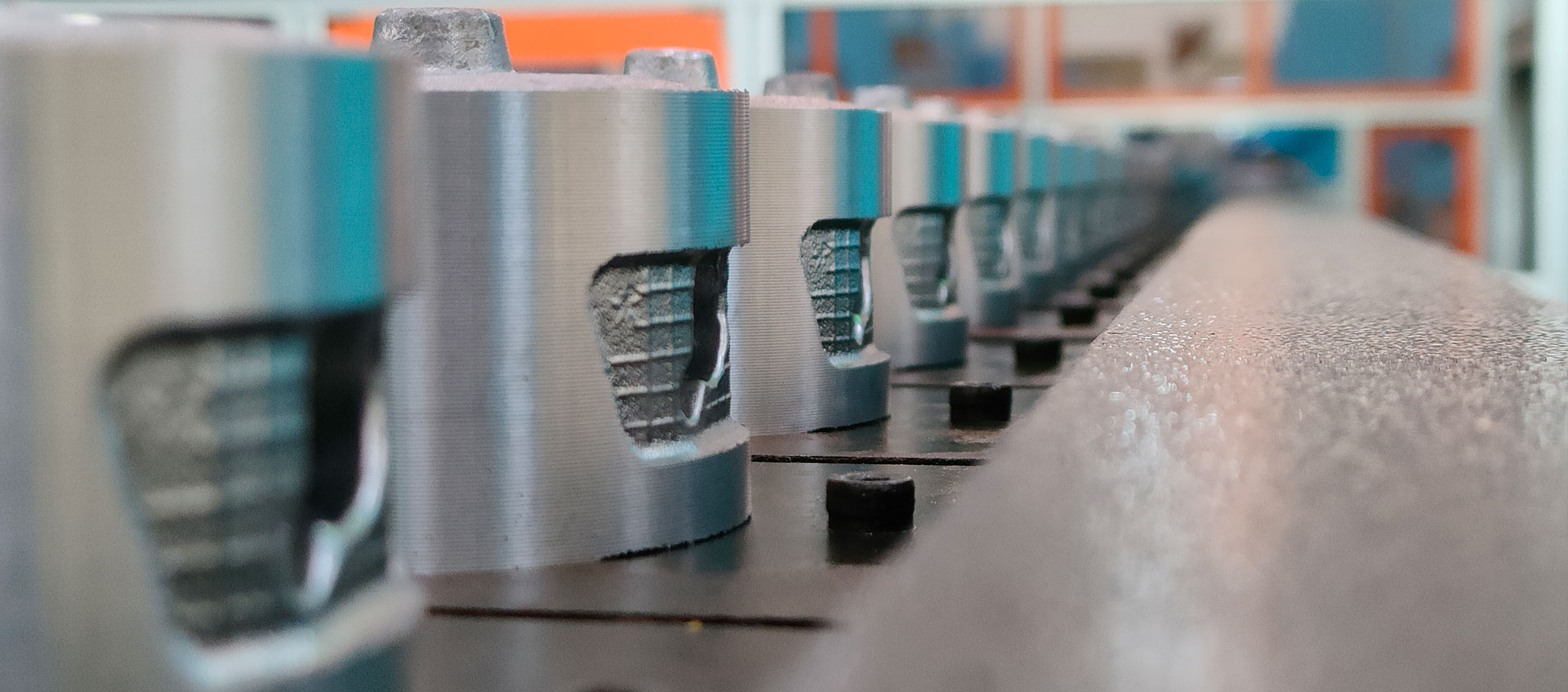

Atlas D.I.D (Private) Limited is a Joint Venture with Daido Kogyo Co., Ltd Japan to produce high quality Drive and Cam Chains. Atlas D.I.D has state of the Art Assembly, Press, Heat Treatment and Forming.

Drive Chain:

The primary function of a drive chain is to transfer rotational motion from engine to the wheel. This allows the machine to move or perform work.

Salient Features:

Reduced wear rate

Long Operational life

Light Weight

Solid bush technology

Excellent oil retention

Reduced Power Loss

Suitable for family motorcycles

Excellent oil retention

Reduced Power Loss

Suitable for family motorcycles

CAM Chain:

CAM Chains are used in motorcycle engines to transmit the rotation of the crankshaft to the camshaft. This chain has a smooth, round surface that supports abrasion and performance.

Salient Features:

Long service life

Reduce Wearing Elongation

Cover all size and suitable for heavy use

For family and general motorcycles

Website: Home - Atlas D.I.D

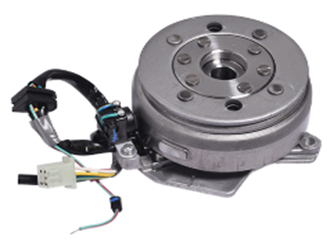

Atlas Hitec (Private) Limited is a Joint Venture with Denso Corporation Japan involved in production of high-quality Regulators, CDI Units and ACG Flywheel.

Alternate Current Generator (ACG)

The purpose of ACG is to generate power for lighting circuit, battery charging circuit and Ignition circuit of system of motorcycle. The Rotor of ACG is also served as Flywheel for Engine and also support to generate pulses for CDI.

Capacitor Discharge Ignition (CDI)

The purpose of CDI is to control ignition timing by input pulsar signal received form ACG. It takes power from ACG and internal capacitor discharges energy into primary winding Ignition Coil at right time according to the ignition timing.

Regulator Rectifier

Regulator Rectifier converts Alternating Current into Direct Current. Technically this operation is known as Rectification. Second function of Regulator Rectifier is to stabilize the voltage to avoid head lamp over voltage and Battery overcharging.

Website: Atlas Hitec Pvt Ltd

Atlas GCI (Private) Limited is a Joint Venture with Gongcheng Chongqing Investment Company Ltd involved in production of Circuit Assembly.

CIRCUIT ASSEMBLY:

CDI Circuit Assembly

CDI (Capacitor Discharge Ignition) purpose is to control ignition timing by input pulsar signal received form ACG. It takes power from ACG and internal capacitor discharges energy into primary winding of Ignition Coil at right time according to the ignition timing.

AGCI is manufacturing Circuit Assembly of CDI Unit by assembly of surface mount and through-hole Electronic components by reflow and wave soldering process. Currently AGCI is producing following models CDI Circuit Assemblies:

CD70

CG125

CB125 F

CG125 Self

Website: Atlas GCI Pvt Ltd

Technical Collaborations

To maintain its high standards of safety, reliability and performance, the Company has also entered into technical collaboration agreements with the following international partners:

Hitachi Astemo Co. Ltd.

(formerly as Showa

Corporation, Japan & Keihin Corporation, Japan)

Honda Foundry Co. Ltd.

Toyo Denso Co. Ltd.

Atsumitec Co. Ltd.

Yamada Mfg. Co. Ltd.

FCC Co. Ltd.

Hitachi Astemo

Co. Ltd.

(Since 1988)

Honda Foundry

Co. Ltd.

(Since 1994)

Toyo Denso

Co. Ltd.

(Since 2001)

Atsumitec

Co. Ltd.

(Since 2004)

Yamada Mfg.

Co. Ltd.

(Since 2006)

FCC

Co. Ltd.

(Since 2009)

Shock Absorber

Atlas Engineering assembles shock absorbers from parts produced in-house as well as from purchased parts. Several related shops have been systematically added over the years for manufacturing sub components of shock absorbers under strict quality control standards in Technical Collaboration with Hitachi Astemo Ltd, Japan. Following are the shops related to the Shock Absorber Assembly which are also located at Sheikhupura premises.

Gravity Casting:

The shops have multiple GDC

machines to cast Case Bottom (one of the main

parts of front shock absorber), Piston and

Bridge Fork Top for motorcycles.

Case Bottom Machining:

Case Bottom machining shop is

machining Case Bottom for motorcycles.

Case Damper:

Case Damper is a part of rear

shock absorber. This shop carries out projection

and condenser welding of Case Damper of

motorcycles.

Buffing:

Buffing Shop is divided into two

portions. One portion uses belt type buffing for

the buffing of Case Bottoms. Whereas, the other

portion uses buffing emery wheel to buff Crank

Cases and Covers Crank Cases of

motorcycles.

CAD/CAM (Computer Aided

Design):

This shop uses three axis

machining centers integrated with latest

computer software for maintenance of dies used

for gravity die casting machines.

Rear Cushion CD 70

Rear Cushion CD 70

Rear Cushion CG 125

Front Fork CD 70

Rear Cushion CG 125

Front Fork CG 125

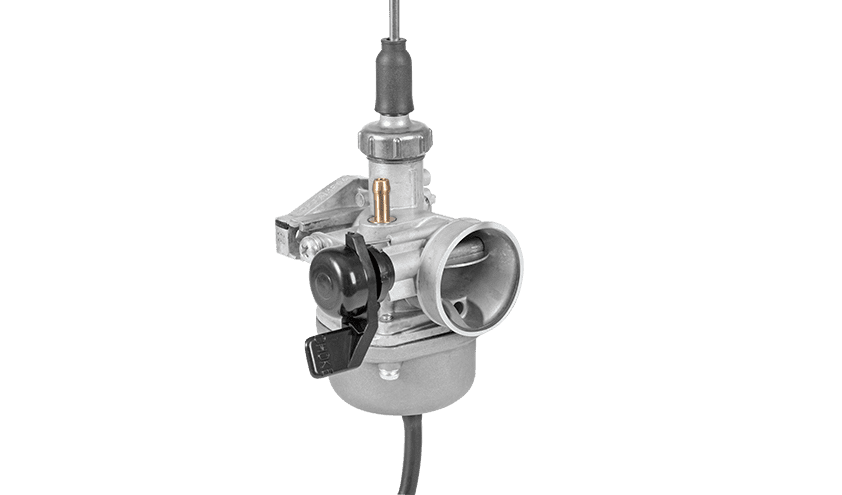

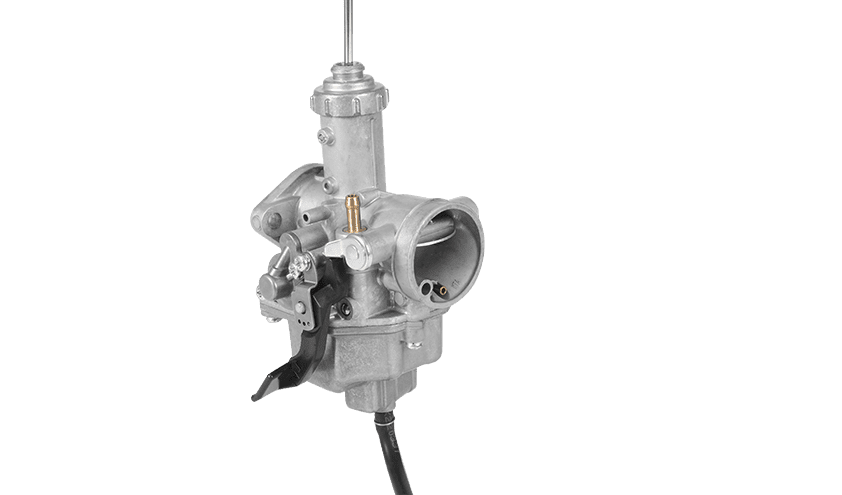

Carburetor

Atlas Engineering manufactures Carburetor of Motorcycles. To ensure adherence to the profoundly established quality principles of Honda Motorcycles, Atlas Engineering signed a Technical Collaboration Agreement with Hitachi Astemo Limited, Japan, one of the principal names in Carburetor technology across the world.

The Carburetor shop has state-of-the-art machinery to maintain the

high standard of the product.

Assembly & Inspection:

Carburetor facility was established in order to adhere extensive quality demand of Honda Motorcycle. State of the Art Machinery including inspection and testing machines were set up to support the stringent quality requirements.

Die Casting &

Machining:

Assembly was expanded vertically

to include Casting, Machining and Surface

Treatment areas to the forte, with addition of 2

Hot Chamber Die Casting Machines and 22 No's. of

CNC Machines were installed.

Carburetor CD 70

Carburetor CG 125

Carburetor CB 125F

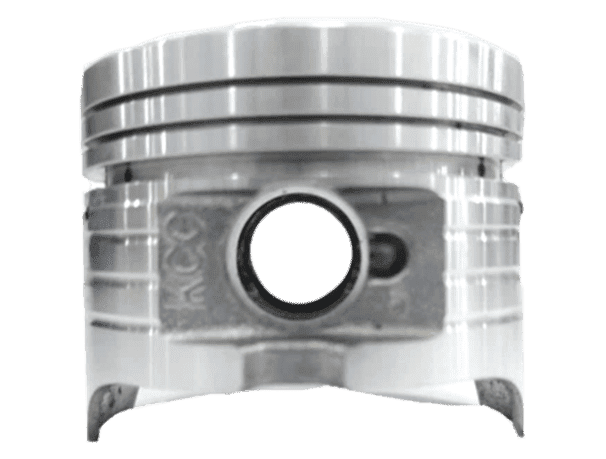

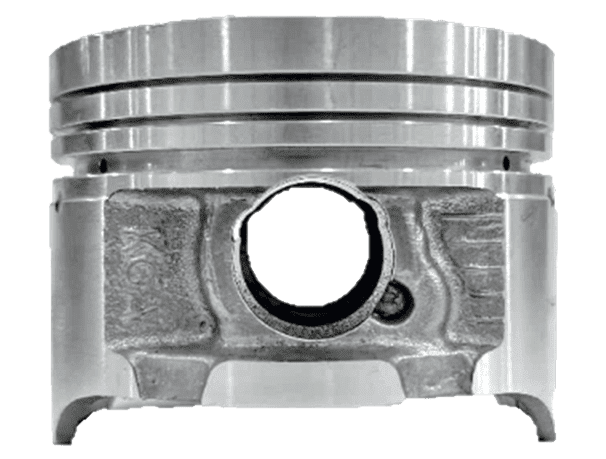

Honda Foundry

Atlas Engineering has state of the art Piston Manufacturing Facility to produce Pistons for Honda Motorcycles. To ensure the quality requirements and intricacy of this crucial engine component, Atlas Engineering has a Technical Collaboration Agreement with Honda Foundry Co. Ltd. Japan one of the pioneers of Piston Manufacturing. The Technical Collaboration took place in 1994.

Piston CD 70

Piston Pridor

Piston CG 125

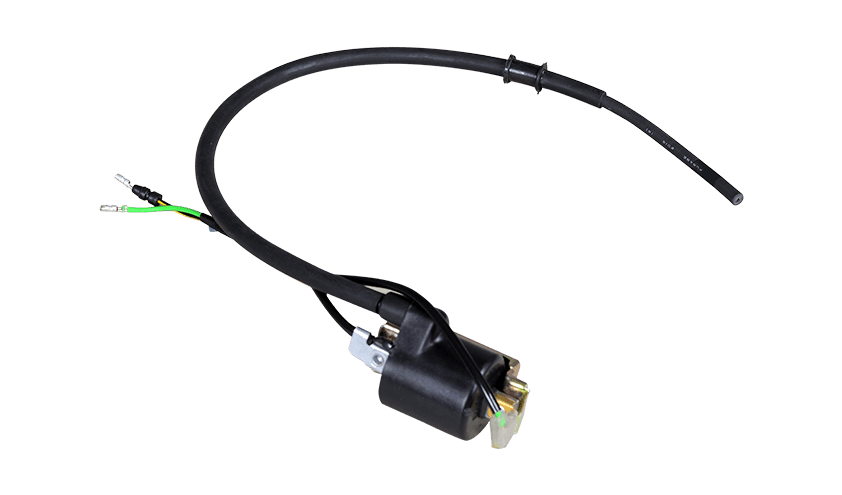

Toyo Denso

Atlas Engineering manufactures Ignition Coil for Honda

motorcycles. To ensure the quality

requirements and delicacy of this electrical component Company has a

Technical Collaboration Agreement

with Toyodenso Co. Ltd, Japan one of the leading Electrical

Components maker worldwide.

The Ignition Coil shop comprises of the following State of the art

manufacturing and Inspection

facilities that ensure the quality product.

Winding:

Copper Winding is the prime

section before the assembly of ignition

coil which is being done by Automatic winding machines

that not only maintain

accuracy and precision but also establish the

base of a Quality product.

Potting:

In order to keep the part in

working condition, a robust layer of

Resin is filled so as to protect the part from

any damage. This is done with the

help of state of the art Automatic Japanese

Machines that ensure the part is

preserved as per required quality standards. The

material is hardened in the

ovens.

Final Inspection and

Assembly:

Epoxy filled coils are assembled

with High Tension cords and are

subjected to stringent quality standards to

comply and deliver premium quality.

Coils are tested at High Voltage device ranging

up to 45 kV in order to check the

performance level in real time. After assembling

noise suppressors, finished product

has to bear final Spark inspection test to

ensure coil fulfills the standards of

Honda Motorcycles.

Ignition Coil CD 70

Ignition Coil CG 125

Ignition Coil Pridor

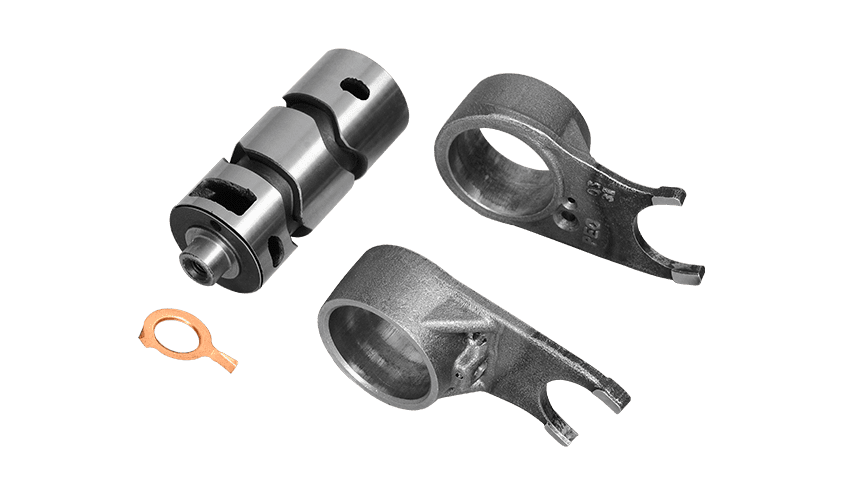

Atsumitec

Atlas Engineering manufactures drum gear shift for Motorcycles and to meet the trademark quality of Honda Motorcycles, it has entered into Technical Collaboration Agreement with Atsumitec Co. Ltd., which is a Japanese based automobile company involved in manufacturing of automobiles parts globally. The shop contains heat treatment facility as well as facility for processing drum in carburizing and tempering furnaces.

Drum Gear Shift CD 70

Drum Gear Shift CG 125

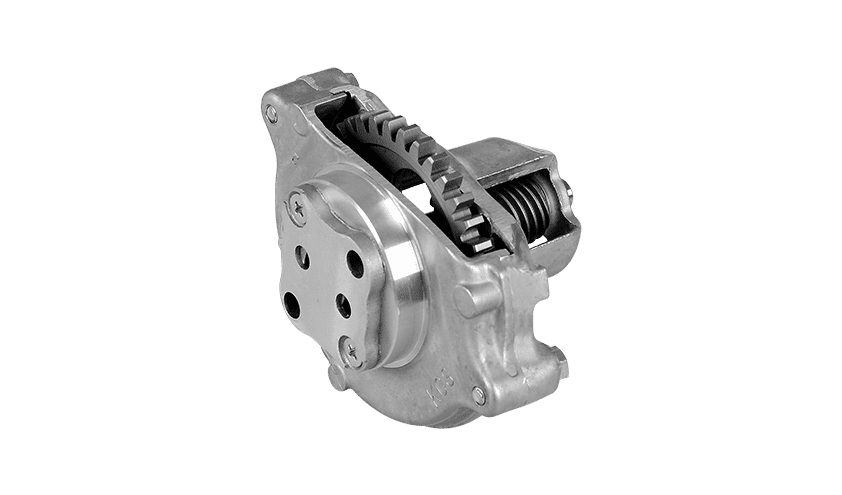

Yamada

Atlas Engineering manufactures oil pumps for Honda

motorcycles. To maintain the high quality standards of customers.

Company has entered into a technical collaboration agreement with

Yamada Manufacturing Co., Ltd Japan.

The product is being manufactured through latest technology set up

and quality measurements are taken with Hi-Tech instruments having

inspection facilities that ensure the quality product.

Oil Pump CG 125

Oil Pump CB125F

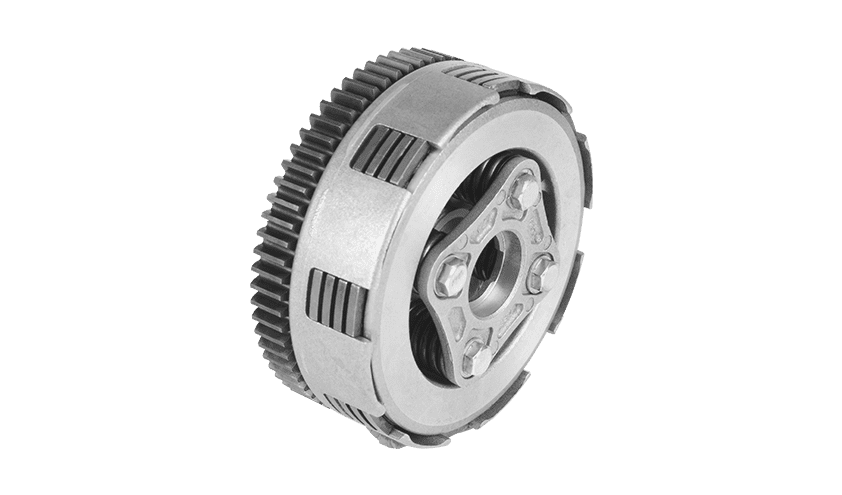

F.C.C.

Atlas Engineering manufactures Clutch for motorcycles. To ensure adherence to the highly demanding quality standards of Honda Motorcycles The Company has entered into a Technical Collaboration Agreement with F.C.C. Co. Ltd. Japan one of the leading names in clutch technology across the globe. The clutch shop comprises of high pressure die casting and machining facilities with the state of the art assembly line.

Clutch CD 70

Clutch CG 125

Clutch CB 125F

Clutch Pridor